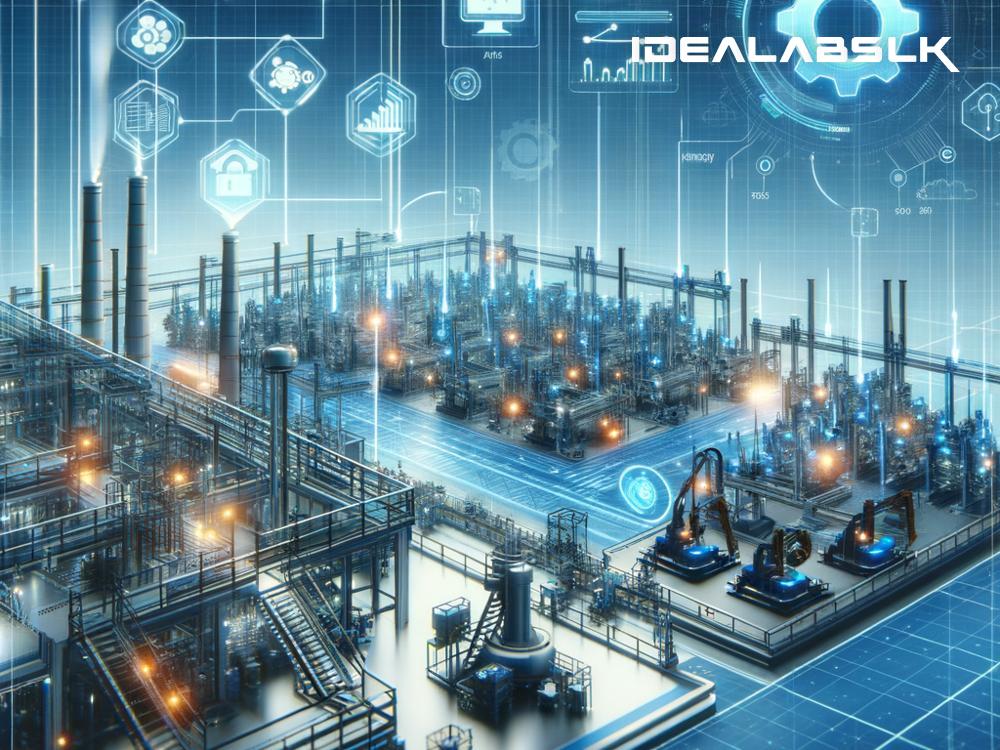

Title: Unveiling the Magic of Digital Twin Technology in Manufacturing

In the ever-evolving world of manufacturing, there's a new kid on the block that's making waves and revolutionizing how products are designed, produced, and maintained. This game-changer is known as Digital Twin Technology. Imagine having a virtual replica of a physical product or process that you can use to experiment, analyze, and optimize without the fear of making costly mistakes on the real thing. Sounds like a dream, right? Well, that's exactly what digital twin technology brings to the table. Let's embark on an exciting journey to explore what digital twin technology is all about, how it works, and the incredible benefits it offers to the manufacturing industry.

What is Digital Twin Technology?

At its core, digital twin technology involves creating a highly detailed and dynamic digital representation of a physical object or system. This virtual model is not a static blueprint; it is updated in real-time with data from sensors embedded in the physical counterpart, creating a living mirror that reflects the current state of the real-world object. This innovative approach allows engineers and manufacturers to test changes, predict outcomes, and troubleshoot issues virtually before applying them in reality.

How Does It Work?

The magic of a digital twin begins with capturing detailed information about the physical object, such as dimensions, properties, and operational data. This information is then used to create a digital replica in a simulation software. Sensors placed on the physical object collect data on its performance and conditions, which is continuously fed back into the digital twin. This real-time data exchange ensures that the virtual model accurately mimics its physical counterpart in every aspect, from how it operates to how it responds to different environments and stressors.

The Power of Visualization and Prediction

One of the most fascinating advantages of digital twin technology is the power of visualization. You can interact with the digital twin in a virtual environment, rotate it, zoom in on components, and see how it functions under various conditions without the logistical challenges of manipulating the physical object. This not only enhances understanding and communication within teams but also significantly speeds up the design and troubleshooting processes.

Moreover, because the digital twin evolves along with its real-world counterpart, it serves as a predictive tool, identifying potential issues before they become problems. For instance, it can forecast when a part is likely to fail based on its current condition and usage. This proactive approach to maintenance can save companies a significant amount of time and money.

Beyond the Prototype: Lifecycle Management and Customization

Digital twin technology excels not just in the design and production phases but also throughout the entire lifecycle of a product. Since the digital twin continuously updates with operational data, manufacturers can use this information to improve future designs, enhance performance, and even offer personalized recommendations to customers based on how they use a product.

For custom manufacturing, digital twins offer a unique advantage. Manufacturers can create a specific digital twin for a customized product, allowing both the producer and the customer to understand and agree on what is being made like never before. This decreases errors and increases customer satisfaction.

Embracing Digital Twins in Manufacturing

Embracing digital twin technology in manufacturing opens a world of possibilities for innovation, efficiency, and quality improvement. It's not just about avoiding errors or predicting failures anymore; it's about reimagining how products are designed, made, and maintained. From aerospace to automotive, and beyond, industries are starting to harness the power of digital twins to stay ahead of the curve in a competitive global market.

Conclusion

Digital twin technology represents a leap forward in manufacturing. By bridging the gap between the physical and digital worlds, it enables companies to avoid costly mistakes, innovate faster, and deliver products that better meet the needs of their customers. As this technology continues to evolve and become more accessible, its impact on the manufacturing industry will undoubtedly grow, leading to smarter, more efficient production processes and products that were once the stuff of the imagination. Let's embrace the digital twin revolution and witness the transformation it brings to manufacturing.