The Dawn of Robots in Industrial Automation: A Historical Journey

In a world where technology evolves at an unprecedented pace, the story of robots in industrial automation marks a significant milestone in human ingenuity. This journey, which began several decades ago, has reshaped the landscape of manufacturing and production industries, ushering in an era of efficiency, precision, and innovation. Let's take a trip down memory lane and explore the first uses of robots in industrial automation, understanding how these mechanical marvels started transforming the way we create and produce.

The Birth of Industrial Robots

The concept of robotics isn't a 21st-century phenomenon. In fact, the seeds of robotic automation were sown as early as the 20th century. The first industrial robot, "Unimate," made its debut in 1961, at a General Motors plant in New Jersey, USA. Unimate wasn't your typical humanoid robot that science fiction had promised, but it was revolutionary. It was a programmable robotic arm designed to perform tasks that were dangerous, tedious, or unpleasant for humans. Its initial jobs included handling hot metal parts and spot welding, tasks that were not only hazardous but also extremely monotonous for human workers.

The Evolution of Industrial Robots

After Unimate's successful implementation, the idea of using robots for industrial purposes gained momentum. Companies and engineers began to see the potential benefits of integrating these mechanical helpers into their production lines. The 1970s and 1980s witnessed the evolution of industrial robots, with advancements in technology making them more versatile, accurate, and reliable. Robots began taking on more complex tasks such as assembly, painting, and quality inspection.

One notable robot from this era was the PUMA (Programmable Universal Machine for Assembly), developed by Unimation with support from General Motors. PUMA's design allowed for more precise and intricate tasks, pushing the boundaries of what robots could achieve in an industrial setting.

The Impact of Robotics in Industrial Automation

The introduction of robots into the industrial sector had a profound impact. They brought about a revolution, ushering in the age of automation. Here are a few ways these mechanical tools transformed the industry:

- Efficiency and Productivity: Robots can work 24/7 without breaks, vacations, or shifts changes, significantly increasing the output of production lines and reducing the time to market for products.

- Precision and Quality: With their ability to perform tasks with high precision repeatedly, robots have helped in reducing errors and improving the overall quality of products, which is particularly critical in industries like automotive and electronics.

- Safety: By taking over dangerous tasks, robots have made workplaces safer for human employees, reducing accidents and injury rates.

- Economic Impact: While there's a debate about robots replacing human jobs, they also create new opportunities in robot maintenance, programming, and supervision, highlighting the shift in the nature of work.

The Modern Age and Beyond

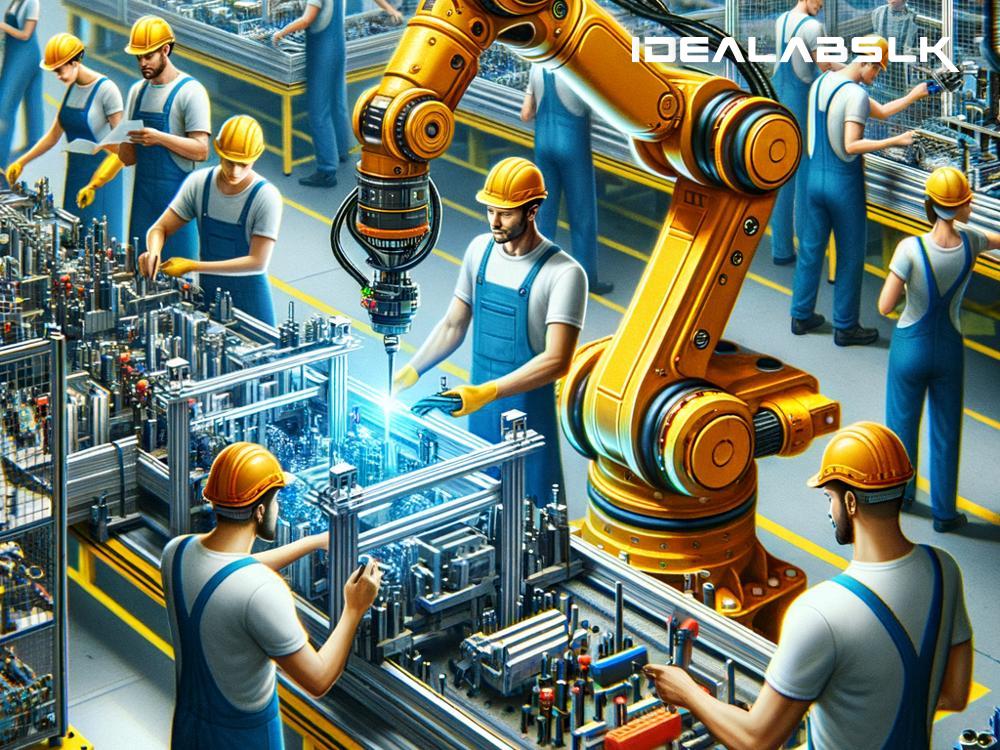

Today, the realm of industrial robotics is more dynamic than ever. With advancements in artificial intelligence (AI), machine learning, and sensor technology, robots are becoming even more intelligent and adaptable. Collaborative robots or "cobots" work alongside humans, capable of learning and adjusting to new tasks with minimal programming.

The future of industrial automation is poised for exciting developments, with robots taking on roles that were once deemed impossible. From delicate surgeries to deep-sea exploration, the potential is limitless.

Conclusion

The journey from Unimate to the sophisticated collaborative robots of today encapsulates the incredible advancements in technology and its application in industrial automation. The first uses of robots in the manufacturing and production industries paved the way for a transformative change, reinventing the notions of efficiency, safety, and innovation.

As we stand on the cusp of further breakthroughs, it's clear that the story of robots in industrial automation is far from over. It's a testament to human creativity and the relentless pursuit of progress. The robots of yesterday laid the foundation for the automated wonders of today and the unimaginable possibilities of tomorrow. In this epoch of technological evolution, one thing is certain — robots will continue to play a pivotal role in shaping our world, pushing the boundaries of what humans and machines can achieve together.