The Future of Space-Based Manufacturing: How 3D Printing and AI Are Transforming the Way We Build in Space by 2024

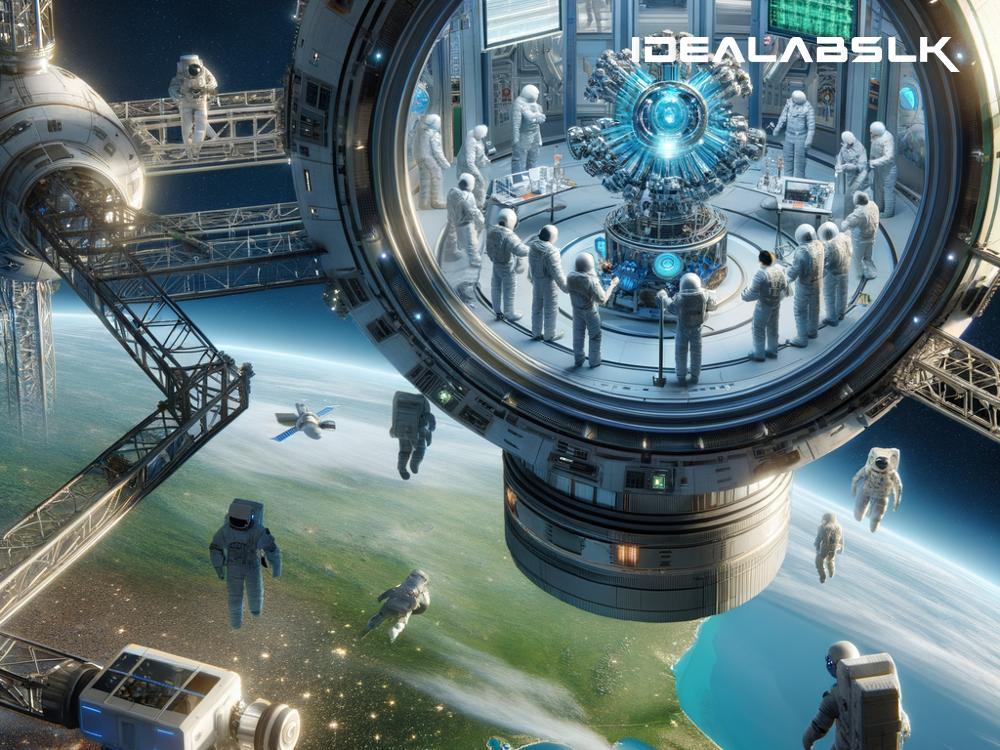

Imagine a world where satellites repair themselves, space stations expand on their own, and astronauts get new tools or habitats built directly in space, all without needing to ship huge, heavy parts from Earth. This might sound like a scene from a sci-fi movie, but thanks to the incredible advancements in 3D printing and artificial intelligence (AI), this future is closer than you think. By 2024, the way we construct and manufacture in the vast emptiness of space could be completely revolutionized.

The Magic of 3D Printing in Space

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by adding material layer by layer, following a digital design. This technology has been around on Earth for a while now, revolutionizing industries from automotive to healthcare. But when we take 3D printing into space, it's a whole new ballgame.

In space, every ounce of weight matters because it costs a lot to send stuff from Earth's surface beyond our atmosphere. This is where 3D printing shines; instead of launching everything we might need into space, we can just send up the printers and raw materials. Need a new wrench or a satellite part? Just print it!

AI: The Brain Behind the Operation

Now, combine 3D printing with artificial intelligence, and you've got a real game-changer for space manufacturing. AI can manage the entire printing process, from design adjustments to actual printing, without human intervention. This is crucial in an environment as unpredictable and harsh as space.

For instance, if a tool breaks on the International Space Station (ISS), astronauts currently have to wait for the next supply shipment from Earth to get a replacement. But with AI-driven 3D printing, astronauts could simply tell the system what they need, and voilà, the tool is printed on demand. This could save valuable time and resources.

Moreover, AI can continuously learn and improve the manufacturing process, adapting to the unique challenges of space environment – like extreme temperatures or cosmic radiation. This constant adaptation ensures that the manufacturing process becomes more efficient and reliable over time.

Transforming Space Construction by 2024

By 2024, these technologies may build not just tools and small parts, but entire spacecraft components, habitats, and even complex mechanisms. Imagine constructing large structures directly in orbit, piece by piece, like assembling a giant Lego set in zero gravity. This would significantly reduce the costs and risks associated with space exploration and colonization.

One exciting project in the pipeline involves using Moon or Mars dust (regolith) as a printing material. This means future moon bases or Mars habitats could be built using the very soil astronauts walk on, dramatically reducing the need to transport construction materials from Earth.

Challenges and Solutions

However, space-based manufacturing doesn't come without its challenges. Microgravity, space radiation, and extreme temperatures can all affect the printing process and material properties. But scientists and engineers are already finding solutions, such as adjusting printing techniques for microgravity and developing new materials that can withstand the harsh conditions of space.

One of the potential solutions involves embedding self-repair mechanisms within the printed objects, harnessing AI to detect and fix any anomalies during the printing process. This ensures that even if something goes wrong, the system can correct itself and continue operating smoothly.

Conclusion

As we stand on the brink of a new era in space exploration, 3D printing and AI are poised to play pivotal roles in making space more accessible and sustainable. By 2024, these technologies could transform how we approach space manufacturing, making it cheaper, faster, and more efficient. From expanding space stations to building lunar bases, the possibilities are as limitless as space itself.

This isn't just about exploring the final frontier; it's about adapting and thriving there. We're not just going to visit space; we're going to live and work there, building the future one layer at a time. Welcome to the future of space-based manufacturing, where the sky is not the limit – it's just the beginning.