Unleashing the Power of Robotics Software in Precision Manufacturing

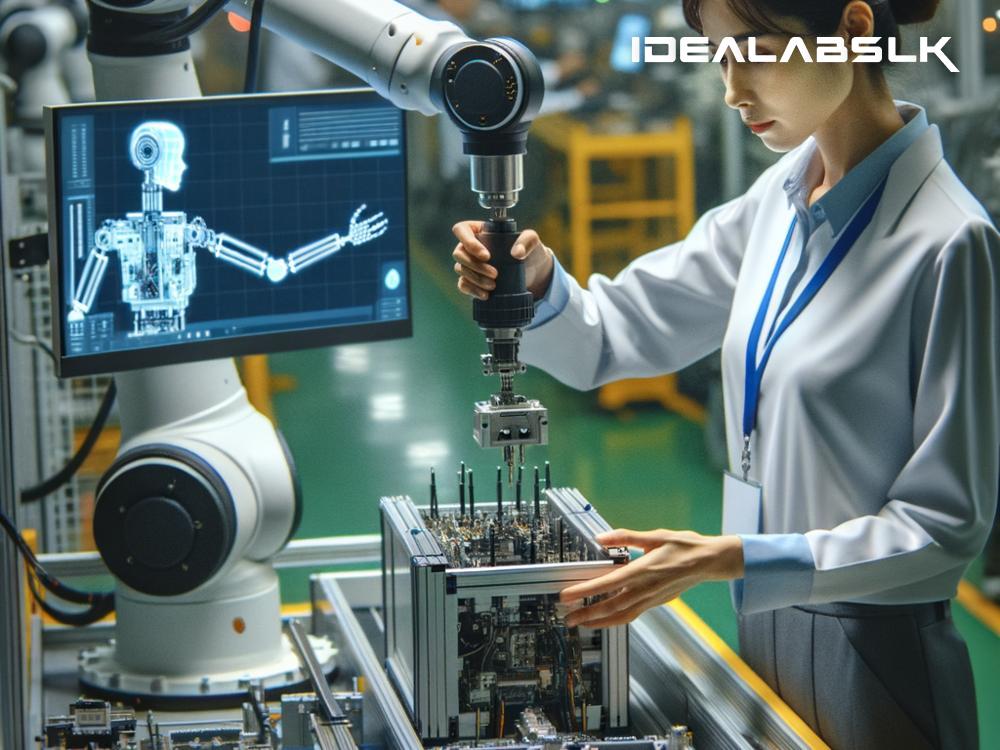

In today's fast-paced world, precision manufacturing stands as the backbone of innovation across numerous industries, from automotive to electronics and beyond. But, have you ever paused to wonder what drives the remarkable accuracy and efficiency behind it? The secret hero behind the scenes is robotics software.

The Magic Wand Behind the Machines

At its core, robotics software is the brain that guides robots to perform tasks with incredible precision. Imagine teaching a human to paint a masterpiece or assemble a watch; it takes a lot of skill and precision. Robotics software does something similar but for robots, enabling them to conduct intricate tasks with the finesse of a master craftsman, but at a speed and consistency no human can match.

The Evolution of Manufacturing

Gone are the days when manufacturing relied solely on human hands and heavy machinery. As technology soared, so did the ambitions of manufacturers to produce items that are not only high in quality but also consistent and produced at scale. Enter the era of precision manufacturing, where the focus is on creating products with exacting standards, every single time. Robotics software is at the heart of this revolution, transforming the way we create, innovate, and deliver.

How Robotics Software Shapes Precision Manufacturing

1. Impeccable Accuracy

First and foremost, robotics software brings unparalleled accuracy to manufacturing processes. Programmed with specific design instructions, robots can produce components with precision down to the smallest detail, which is crucial for industries where even a millimeter's discrepancy can spell disaster.

2. Consistency and Reproducibility

Robots, guided by their infallible software, can repeat the same task with the same level of precision, 24/7, without breaks or human errors. This consistency is invaluable in manufacturing, ensuring that every product off the line meets the high-quality standards set by the company.

3. Increased Efficiency and Productivity

By automating tasks that were traditionally manual, robotics software frees up human workers for more complex, creative, or supervisory roles. This not only boosts productivity but also dramatically reduces the time from design to market, giving companies a competitive edge.

4. Minimizing Waste and Reducing Costs

Precision is not just about making things perfect; it's also about reducing waste. Robotics software enables robots to work with materials more efficiently, minimizing offcuts and errors that result in waste, and ultimately, saving costs in materials and rework.

5. Enhanced Safety

Let's not forget the safety aspect. Many manufacturing environments are hazardous, involving heavy machinery or toxic substances. Robots, directed by their software, can take over these dangerous tasks, reducing the risk to human workers and fostering a safer work environment.

The Challenges Ahead

While the benefits are vast, integrating robotics software into precision manufacturing also presents challenges. The initial investment can be significant, and there is a learning curve involved in adopting new technologies. Moreover, as the technology evolves, so does the need for continuous updates and maintenance to ensure the robots and their software operate at peak efficiency.

The Future is Now

Despite these challenges, the adoption of robotics software in precision manufacturing is not just a trend; it's a revolution that's reshaping the manufacturing landscape. Forward-thinking companies are investing in this technology to enhance their capabilities, improve product quality, and stay ahead in the competitive global market.

As we look to the future, the role of robotics software in precision manufacturing will only grow. Advances in artificial intelligence and machine learning will enable robots to make decisions, adapt to changes, and even predict maintenance needs, further pushing the boundaries of what's possible.

Conclusion

The fusion of robotics software with manufacturing processes marks a significant leap toward efficiency, safety, and quality in production. As we continue to explore the capabilities of these smart machines, one thing is clear: the future of manufacturing lies in the digital minds of robots, powered by advanced software. This is not just a new chapter in industrial history; it's a whole new book waiting to be written, with robots and humans working side by side to create wonders. In essence, robotics software in precision manufacturing is not just transforming industries; it's shaping the future.